Pages

What is Have Kiln Will Travel?

What is Have Kiln Will Travel?

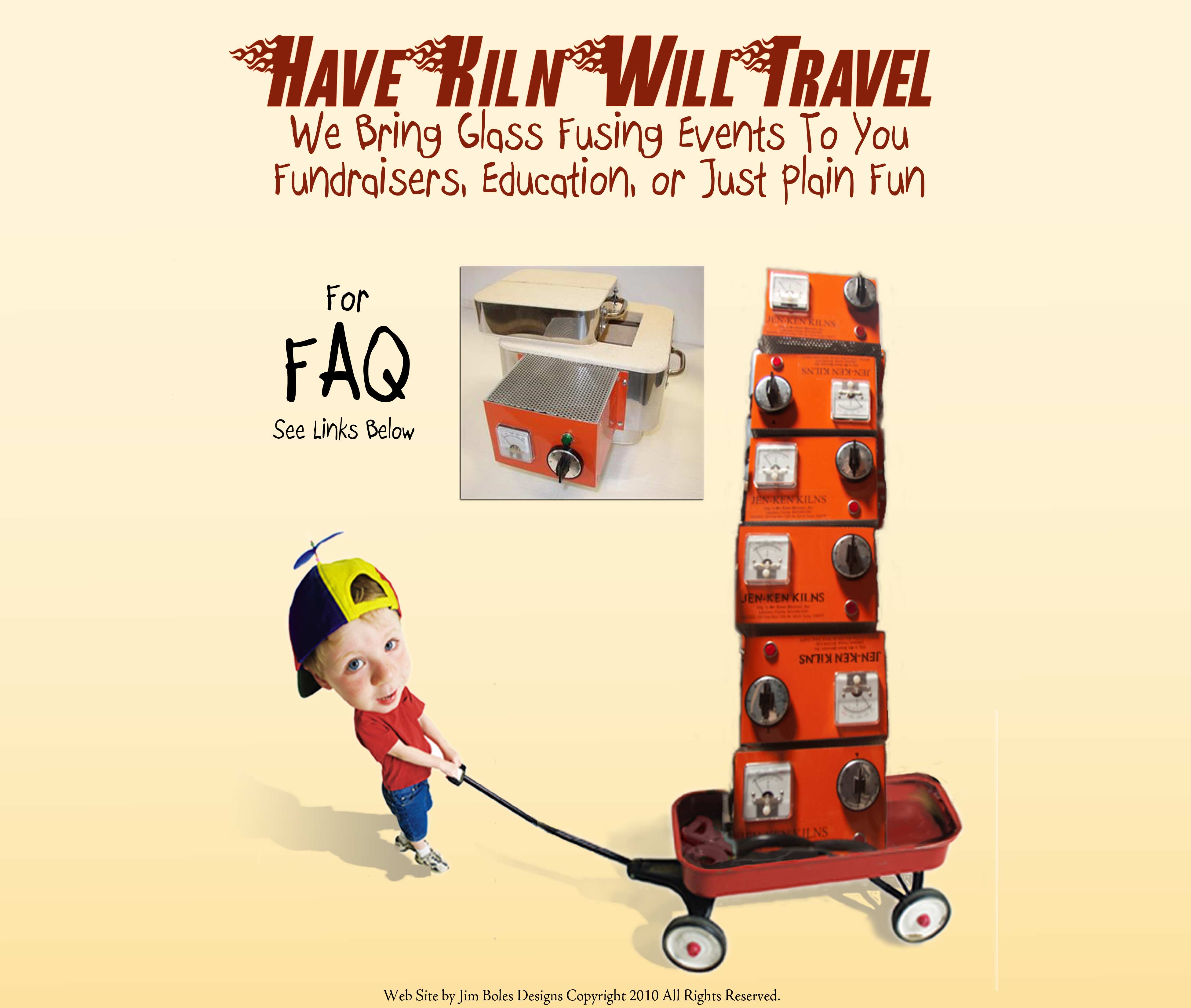

Have Kiln Will Travel (HKWT) is a fully equipped traveling fused glass studio. Six small kilns are brought on site to teach glass fusing along with a large selection of art glass, and all of the necessary tools. It is the only traveling glass studio in the United States servicing art centers and community education programs.

HKWT is truly a unique opportunity and an ongoing experiment in community education. HKWT teaches the basics, gives you the opportunity to watch your creations come alive in the kiln, and for the jewelry classes you take your works of art home that day.

When Are Events/Classes - Use the calendar below for a complete listing of classes and their locations.

Detailed Class Information - Use the "Search Terms" section in the lower left column to find detailed blog posts regarding what is taught and what is made in the classes. There are also class specific descriptions found at the "Information Links" section in the left hand column of this blog.

Where To Register For Classes - Use the "Register For Classes" section for links to the art center or community education program that you are interested in.

Fund-Raising Events - In addition to classes the HKWT concept can be used to raise money for your favorite charitable or nonprofit organization. Use the "Information Links" section to obtain a document with detailed information on hosting a HKWT event.

Blog Archive - Look through the blog (lower left column) for more information on projects.

Calendar Of Events & Classes

----- Have Kiln Will Travel Event Calendar ------ Registration Links Are Below Left of Calendar

Thursday, September 9, 2010

Fused Glass Wind Chime Class @ Eden Prairie Art Center

I often learn as much in my classes as the students do. When there are hundreds of colors, shapes, textures and other additives you literally could never do all the combinations yourself. Then of course there is your personal preferences which would limit you to what YOU like. I get a chance to see so many combinations that I would never try myself.

Doing these little color and shape studies is one the best techniques to learn what particular glass combinations do. Glass changes shape, color, and texture when heated. Consequently, the end result is very often not what you would expect. It takes years, after seeing a lot of projects done, to be able to reliably predict what will occur with particular combinations. By doing a whole series of small studies you can significantly reduce your learning curve.

I always take a picture before and after firing as a reliable record of what was done. Your memory really isn't good enough. In the closeup below you can see some of the glass elements the students used.

I bring a lot of choices to the class including: 100 samples of frit and powder, mica dust and chips, glass shards, rods, stringer, over 50 differ colored sheets and at least 20 different types of iridescent glass in black and clear.

All of the glass in the pictures are individual chimes for the wind chime they will make. There are few rules. You really just put combinations of glass together that you find pleasing. The size and shape of each chime will make a unique sound when struck by the other chimes, resulting in a cacoffiny of ringing.

In each class I also learn a few things to fine tune future classes. This time I realized that the little metal loops used to hang the glass needs to be fused into a small glass strip by me before class. This will enable a student to add a prefused loop to each chime simplifying that step. It was too confusing and tedious for the students to put the hanging loops in place themselves.

I also learned that students can optionally make between 10 and 14 chimes. They don't have to make 14 just because there are 14 holes in the metal support bar. As you can see in the picture to the right 12 chimes is fine. They are close enough to each other to perform their clanging best. Eight chimes would probably be OK too.

In my last class each student made 14 chimes and I think that was too many. But options are always good. Now with 14 they can choose to keep a few as backups in case the chime meets a tornado!

Tuesday, August 24, 2010

Scott County Art Craw - Oct 9th

I'll be participating in the first ever Scott County Art Crawl. Read all about it and see some of the work at http://bit.ly/bRQ7Dh.

Come by for a feast for the eyes, mind and tummy... I'll have great beer, wine and hors d'oeuvres.

Monday, July 12, 2010

Glass Weaving @ Bloomington Art Center

These are small 5 by 5 inch bowls made using the glass weaving approach. This is a great project that teaches the basics of glass cutting. In this case learning to cut exact strips is pretty basic, but can be really intimidating to the beginner. After all, how many people have experience cutting a whole series of exact 10 inch by 1/2 inch strips?

It is a great sense of accomplishment when building your confidence to cut glass to exacting measures. In one of my classes one person was seriously struggling and gave up at one point. After some encouragement and watching others having success she was determined to do it. I watched her carefully, and caught her mistake in the process, then before you knew it she exclaimed "I got it"!... and I was relieved she did.

Glass weaving is a bit of a trick. The Warp is created by placing glass strips on a mold that is nothing but a series of 'hills' and 'troughs'. When you turn the heat on in the kiln the glass slumps (bends) down into the troughs, and the glass strips are bend into a series of "S" or sine wave shapes. The Weft is simply straight pieces of glass that you slip between the hills and valleys of the warp. After 'weaving' straight strips through all of the warp strips you then place the assembly back into the kiln to fuse it all together.

It is a bit of technical curiosity that many students find gratifying on multiple levels. For one, they learn the trick, secondly they learn to cut class, and lastly they begin to see the design potential of altering the colors and thicknesses of the weave patterns just as a cloth weaver would.

If you want to see glass weaving gone mad just take a look at the site by Eric & Marrlow. This is one great example of a good idea taken to new heights.

I will be teaching glass weaving both at the Chicago Avenue Fire Arts Center and at the Bloomington Art Center this fall.

Fossil Flora : Letting Nature Speak For Herself

I've been intrigued by some recent activity in the glass fusing world of people incorporating natural objects like plants into their fusing projects. The image above was my first attempt and I was pleased with the simplicity and the delicate look of the results.Of course fossils don't come in color, but if they did they might look like these images.

I've been intrigued by some recent activity in the glass fusing world of people incorporating natural objects like plants into their fusing projects. The image above was my first attempt and I was pleased with the simplicity and the delicate look of the results.Of course fossils don't come in color, but if they did they might look like these images.So far I don't offer making fossil flora in any of my classes, but the process is simple enough so I will probably incorporate it soon. This project also uses glass paste (see prior blog posts), but this time the paste is created by sifting multiple layers of powder onto a plant.Between each sifting layer you spray the plant with just enough hair spray to wet the powder but not wash it away. With each subsequent layer the powders become thicker, and with each layer you should add different colors, tints and tones to create a complex naturalistic mixture.

What is really interesting is that the ash of the actual plant is left behind as a ghost image. You can rub it off to reveal more color or leave it.

I started experimenting with this process because I may use it in my fine art powder painting series. Maybe I'll let nature speak for herself instead of me faking it by drawing in foliage.

Drawing with Glass: Fused Glass Flower Vase

This series of images show the steps in decorating the front panel of the flower vase project using glass paste. This process is only one of many ways to decorate the front of your vase. Some may not like this approach and may opt for other methods some of which I will show in future blog posts.

This series of images show the steps in decorating the front panel of the flower vase project using glass paste. This process is only one of many ways to decorate the front of your vase. Some may not like this approach and may opt for other methods some of which I will show in future blog posts.If you look closely you a piece of clear glass and been seen coving the design to the left. It is shaped like a pocket and is more pronounced in the second image where the design has been traced onto the glass with black glass paste.

The tracing process can be done in just a few minutes and does not have to be exact, because it will be partly covered in later steps. A few posts back I explained how the paste was made. For this project only the outline cartoon is created with the paste mixture and applied using a squeeze bottle. If I had all of my colors ready to go in bottles, then it would be simple to fill in the design with whatever color I wanted directly from the bottles. However, there are advantages to using straight powders instead such as ease of application, ability to mix colors, and create gradations, tints and tones.

The tracing process can be done in just a few minutes and does not have to be exact, because it will be partly covered in later steps. A few posts back I explained how the paste was made. For this project only the outline cartoon is created with the paste mixture and applied using a squeeze bottle. If I had all of my colors ready to go in bottles, then it would be simple to fill in the design with whatever color I wanted directly from the bottles. However, there are advantages to using straight powders instead such as ease of application, ability to mix colors, and create gradations, tints and tones. In the third image all of the base colors have been applied using powders and a very small sifter.You can see now that some of the outline is beginning to be covered. This not only narrows the lines, but also helps tie the powder to the wet paste so that during firing they don't separate.

In the third image all of the base colors have been applied using powders and a very small sifter.You can see now that some of the outline is beginning to be covered. This not only narrows the lines, but also helps tie the powder to the wet paste so that during firing they don't separate.In the fourth image the powder is now turned to paste by applying glue through another squeeze bottle. This enables packing the powder to increase its density/opacity. The outline is now considerably thinner and the colors are fully integrated with the outline.

You can see in the green I applied two colors of green. The base layer may or may not show through depending on how thickly you apply the final layer. It helps in color blending and creating rich color interactions if you use multiple colors on both the base layer and the final layer.

One drawback however is that some colors do not mix well resulting is brown instead of a color you see when you mix the powders. This occurs mostly when you mix warm and cold colors like yellow some blues. If you want green, then you should use green powder, and then use white or black to create shades and tints, or, use other greens in combination to create a rich palette of greens.

The process including this step takes around fifteen to thirty minutes depending on the complexity of your design.

In the final image a top layer of colors has been added and pressed into the paste. Some #2 frit was randomly applied and now the 'pocket' is ready for fusing onto the back of the vase creating the pocket vase.

Thursday, July 8, 2010

Design Patterns for Stained Glass & Flower Vase Projects

These are four of many patterns which will be available for use for both the Introduction to Stained Glass and Fused Glass Flower Vase classes. The complete set can be found at the "Information Links" in the left hand blog column. The patterns for the vase are size appropriately to fit on the shape of the vase.

For the vase class the pattern will be used to trace onto the glass using glass paste as explained in a prior post. Once you have the outline done then you can fill it in with whatever colored glass powder you wish. It is really easy to do and fun, because you can make any changes easily or even just draw your own design.

This is just one design approaches. There will be other options and a lot of glass to choose from to decorate the front of the vase.

The patterns for the stained glass class are all around 5 by 5 inches, and most will require less than 20 pieces of glass. That doesn't sound like much, but it is an intro class. Leaning to cut glass, grind it to shape, foil it (copper foil) and learning how to solder is a lot to absorb in one afternoon.

Getting the basics down will enable you to do more advanced work, and maybe even create your own patterns from scratch.

Download the PDF files and pick out your pattern and bring it to class!

Wednesday, July 7, 2010

Jewelry Designs

These are examples of some of the design options you have when you attend the Fused Glass Jewelry class. All of these techniques and a lot more will be explained in class. There is a PDF available for you to read before attending the class which will help you to understand how these are other designs are created. Click here for the PDF or find it in the list of "Information Links" in the left hand column.

You will be amazed and pleasantly surprised just how easy it is to create glass art jewelry that you will be proud to wear or give as gifts.

Take for example the bracelet. You will see during class through a little viewing port in the kiln that as glass is heated it tends to gather itself into a rounded shape. The round pieces in the bracelet where actually little squares, but when heated to a high temperature the glass will gather itself into a rounded shape. If you start with a rectangle then the glass gathers into a rounded oval.

Print out the PDF and bring it to class. You will be amazed at all the options you will have in glass selection, techniques, tools, and how much you will learn by sharing everyone's ideas during the class.

Monday, July 5, 2010

Using Glass Paste In Your Designs

This blog post focuses on the use of glass paste in jewelry design. There are various names for this process, but simply put a paste is created by mixing glass powder with a somewhat viscus liquid medium. There are several commercial products on the market you can buy as your medium, Liquid Stringer being one of them. For my medium I use the recipe documented in the video Fritography by Michael Dupille. His medium is CMC based (Carboxymethyl Cellulose) which is a very slimy food additive. When glass powder is added to it the mixture is a fairly think paste which can be put into squeeze bottles and even in a cake decorator bag.

For the item in the image above I used a squeeze bottle and loaded bottles with various color mixtures.The Bullseye glass company makes a lot of different colors so your palette can be fairly extensive. However, you might find powders created by other companies better for this application. The grain size (mesh) of the powder varies a lot between Bullseye's colors. Consequently, some colors clog easily in the squeeze bottle nozzle. When this happens you have to adjust either the mixture ratio (possibly making it too runny), or, increase the nozzle size to get the paste to flow properly. A further note is that you should use a food scale in weighing out your mixture. Getting the mixture just right saves you some aggravation, and noting mixing variations between colors saves you time when making subsequent batches.

Once you have your bottles loaded the fun begins. You simply apply the paste colors in any design you want. For the pendant to the left I used black and white paste. It took a whole five minutes to do.

The steps would be to cut your glass, apply the paste, and let them dry before placing in the kiln. The last step isn't required. You cold put them in wet, but that might cause some bubbling of the liquid during the heating cycle which may distort your design.

There are several other design options. When you fire your glass you can place the piece in the kiln design side down or up. If the paste is down on the shelf then the clear glass base (now on top) will give the piece a nice sense of depth and will be glossy. If the design is up, then the finish will be more mat in appearance, and the design will shrink and distort more. In the case of an abstract design like the picture here the distortions can be pleasing.

The image to the right shows a before and after. These are very simple designs just to get the idea across. Some very intricate and large designs are possible limited only by your imagination or your budget.

The image at bottom right shows glass paste applied in an approximately 6x6 inch square. It was applied in bands of color running left to right in the order of red, black then blue which repeat several times. The mixture of paste was thin enough that a tool could be run through the liquid/paste design, leaving a trail behind. Each vertical line top to bottom is the drag-path of the tool. This technique is called cold raking. The same raking process can be done hot when the glass has been heated to a honey consistency in a kiln and a metal tool is raked through the molten glass, creating the same type of raking path. Cold raking is much safer and controllable of course, because you don't have to go into a hot kiln to do it.

The image at bottom right shows glass paste applied in an approximately 6x6 inch square. It was applied in bands of color running left to right in the order of red, black then blue which repeat several times. The mixture of paste was thin enough that a tool could be run through the liquid/paste design, leaving a trail behind. Each vertical line top to bottom is the drag-path of the tool. This technique is called cold raking. The same raking process can be done hot when the glass has been heated to a honey consistency in a kiln and a metal tool is raked through the molten glass, creating the same type of raking path. Cold raking is much safer and controllable of course, because you don't have to go into a hot kiln to do it.I explain a lot more about the use of powders and paste at my old site (defunct but still available) called EyeCandy. http://www.jimbolesdesigns.com/eyeCandy/ffHowTo.htm

Sunday, June 13, 2010

The Enameling Adventures Begin

Have Kiln Will Travel is now offering copper enameling classes!

Enameling is a very close cousin to glass fusing which HKWT is based on. In a nutshell, enameling is the process of placing glass powder onto copper, then baking it in a kiln until the powder melts into glass and permanently adheres to the copper base.

Enameling is a perfect addition to the HKWT adventures, because it is quick and that helps make it fun. You can make changes to your work very quickly by adding more color or completely covering over and starting again. A single firing only takes a couple of minutes in the kiln, and nothing is lost by repeated firings which encourages you to enhance your efforts and try new ideas.

Enamels are basically ground glass which are heavily pigmented. You use very little, less than 1/16 of an inch, to completely cover the copper base. You can sprinkle it with your fingers, sift it onto your project, create patterns with stencils and apply it wet like paint. There are in fact books full of techniques and you will learn quite a few during a three hour class.

Enamels are basically ground glass which are heavily pigmented. You use very little, less than 1/16 of an inch, to completely cover the copper base. You can sprinkle it with your fingers, sift it onto your project, create patterns with stencils and apply it wet like paint. There are in fact books full of techniques and you will learn quite a few during a three hour class.Like a lot of art forms the basics of enameling are learned quickly, however you could also spend a lifetime and not uncover all of its secrets. The class will focus on a few technical details like preparing the copper, how and when to use binders/glue, and you will be introduced to the basic tools and equipment.The butterflies to the left show what the copper looks like before and after putting the first layers of enamel on. A typical piece may be fired three to five times before you are satisfied with the colors. Some of the enamels are transparent and the thicker you put them on the more intense the colors become. Some of the most beautiful professional pieces may be fired as many as thirty times. This gives a piece smooth gradations, color intensity and a great sense of depth.

The shapes are machine stamped pieces of 20 gage copper which is approximately 1/16 inch thick. I ordered approximate 40 different shapes ranging in size from 1/2 inch to several inches. The shapes and the enamels are included in the cost of the class. The largest shapes however cost 50 cents each. Copper as you know is becoming expensive. Many of the items can be turned into pendants, pins and earrings and the hardware/findings for these can also be purchased.

The shapes are machine stamped pieces of 20 gage copper which is approximately 1/16 inch thick. I ordered approximate 40 different shapes ranging in size from 1/2 inch to several inches. The shapes and the enamels are included in the cost of the class. The largest shapes however cost 50 cents each. Copper as you know is becoming expensive. Many of the items can be turned into pendants, pins and earrings and the hardware/findings for these can also be purchased.At the end of class it is great fun to turn your work into a finished piece of jewelry when adding the findings. Everyone shares in the excitement of seeing all the work that was completed, and we all learn from the different approaches taken for color choices, application techniques and design.

Because enamel is glass you can also use enameling as part of a fused glass project where the enamel is placed on a glass sheet instead of copper. We will start to do this in future Fused Glass Jewelry classes. The only thing to keep in mind is that the enamel set for fused glass is different from the set used on copper. You use them the same way, but they are not compatible. Kind of like mixing oil paints with acrylics - you just can't do it. The result would be a cracked and broken project after it comes out of the kiln.

Because enamel is glass you can also use enameling as part of a fused glass project where the enamel is placed on a glass sheet instead of copper. We will start to do this in future Fused Glass Jewelry classes. The only thing to keep in mind is that the enamel set for fused glass is different from the set used on copper. You use them the same way, but they are not compatible. Kind of like mixing oil paints with acrylics - you just can't do it. The result would be a cracked and broken project after it comes out of the kiln.Some of my repeat students who have been through the enameling class and have attended the fused glass class could attend a class and do anything they want - either enameling projects or fused glass jewelry or even using enamels in a jewelry piece!

This is really incredible... I'm thinking as I'm typing... not only is HKWT a unique experience, but we will also be combining media in ways seldom seen. I can't wait to see what happens!

Those who have had one of my longer running classes at an art center know that I'm highly experimental in my approach. I love to try to do things in new ways, mixing it all up just to see what comes out. The great thing about teaching is that that the students are mixing it up for me. As they discover new textures and application techniques the best thing I can do is just keep my mouth shut and not ruin things by saying "that's not how I would do it". Of course I steer them away from obvious pitfalls, but there is a fine line between doing something 'wrong' and discovering something new.

Eventually, at one of my art center classes we will make our own large copper shapes out of sheets of copper. We will then fuse the copper partly into glass, leaving some of it outside the glass. The part outside of the glass can then be bent into a third dimension and copper enamels applied to it. This of course is now taking enameling into the realm of larger sculptural forms, but it all starts with the basics - just applying enamels to machine stamped shapes... pretty simple - but there is no telling where we will go from there.

Friday, May 21, 2010

Have Kiln Will Travel - On The Road!

I have been spending a lot of my time planning out the fall season of HKWT events. There will be over 20 sites where classes and events will be held this fall, and brand new classes too.

I am especially excited to be teaching at the Edina Art Center and the Hopkins Center For The Arts for the first time this fall. I will be returning to the Bloomington Art Center to repeat the successful six week Introduction To Glass Fusing, and will feature the student's work here in a few weeks after the projects are completed.

I am also proud to be teaching for the first time in my home town of Savage at the Savage Art Studios & Gallery. I hope to form a long standing relationship with my neighbors there.

The link for all of these locations is to the left.

Some of the new projects are shown here. The Art Glass Wind Chime is fun to make. Students learn some basic glass cutting skills and get to choose what type and color of glass they want to use. They also do all the stringing using fishing line and crimps. They sound really great. I was surprised at the quality of the sound when I made the first one and hung it. Each piece of glass creates its own sound based on the overall size and shape so no two chimes sound exactly alike! Unfortunately, unlike the jewelry class, we do not do the fusing during the class. The finished pieces will be mailed to students.

The Fused Glass Jewelry (and much more... hint, hint guys) is being offered many times over the coming months. It remains an amazing day of learning, sharing, and fun.

The Art Glass Flower Vase class is a new addition. Students will create a

pocket vase which will hang on a wall. They will choose what glass they want for the front and back and they will decorate the front with glass elements. One technique is to use glass paste in a cake decorator bag and squeeze out a design just like you would for decorating a cake. It is actual glass and when fused the design is transformed into permanent glass. Many glass options are provided to create the vase which is hung by to braided copper loops fused into the glass. Students will learn how to braid copper wire to form the attractive hanging loops.

Another new course is an Introduction to Enameling. This will be a wonderful adventure in glass on metal as some folks call it. Enamels are finely ground glass with very intense pigments so you don't need that much to make a bright colorful design. It is so much fun watching the enamels melt into glass right before your eyes in minutes. The little kilns have viewing ports so you can watch the transformation happen. You can add layers of colors and repeatedly fire the enamel to build very interesting designs, gradations, and textures.

Regular glass fusing takes many hours to perform its magic. Enameling on the other hand is the craft for those who can't wait! Instant gratification, or should I saw glassification!

Forward the link to HKWT to your friends. Their is bound to be a class in your area.

I am especially excited to be teaching at the Edina Art Center and the Hopkins Center For The Arts for the first time this fall. I will be returning to the Bloomington Art Center to repeat the successful six week Introduction To Glass Fusing, and will feature the student's work here in a few weeks after the projects are completed.

I am also proud to be teaching for the first time in my home town of Savage at the Savage Art Studios & Gallery. I hope to form a long standing relationship with my neighbors there.

The link for all of these locations is to the left.

Some of the new projects are shown here. The Art Glass Wind Chime is fun to make. Students learn some basic glass cutting skills and get to choose what type and color of glass they want to use. They also do all the stringing using fishing line and crimps. They sound really great. I was surprised at the quality of the sound when I made the first one and hung it. Each piece of glass creates its own sound based on the overall size and shape so no two chimes sound exactly alike! Unfortunately, unlike the jewelry class, we do not do the fusing during the class. The finished pieces will be mailed to students.

The Fused Glass Jewelry (and much more... hint, hint guys) is being offered many times over the coming months. It remains an amazing day of learning, sharing, and fun.

The Art Glass Flower Vase class is a new addition. Students will create a

pocket vase which will hang on a wall. They will choose what glass they want for the front and back and they will decorate the front with glass elements. One technique is to use glass paste in a cake decorator bag and squeeze out a design just like you would for decorating a cake. It is actual glass and when fused the design is transformed into permanent glass. Many glass options are provided to create the vase which is hung by to braided copper loops fused into the glass. Students will learn how to braid copper wire to form the attractive hanging loops.

Another new course is an Introduction to Enameling. This will be a wonderful adventure in glass on metal as some folks call it. Enamels are finely ground glass with very intense pigments so you don't need that much to make a bright colorful design. It is so much fun watching the enamels melt into glass right before your eyes in minutes. The little kilns have viewing ports so you can watch the transformation happen. You can add layers of colors and repeatedly fire the enamel to build very interesting designs, gradations, and textures.

Regular glass fusing takes many hours to perform its magic. Enameling on the other hand is the craft for those who can't wait! Instant gratification, or should I saw glassification!

Forward the link to HKWT to your friends. Their is bound to be a class in your area.

Sunday, April 11, 2010

North St. Paul HKWT Event @ Maplewood

The glass fusers are a-buzz, hovering over a fresh batch of fused glass eye candy. It is always exciting each time we take the lid off of a kiln and see the hot new creations in glass. It is very surprising actually, because the glass not only changes shape slightly, but it may also change in color and texture.

It is very common that participants are so involved in making one piece after another that they often forget what is theirs in the kiln! It never fails that there are a few pieces which two different fusers think are theirs, but after a short discussion someone realizes that the piece probably isn't theirs. At the same time there are a few pieces which no one recognizes as theirs. I call these poor lost gems orphans, and after some encouragement someone in the group adopts them.

Here are a few gems from the Maplewood adventure in glass fusing.

Friday, April 9, 2010

Samples from Rosemount Community Ed. Event

Another fun day of glass fusing was had at the Rosemount MN Community Ed. program. We did a record eight firings and well over 100 pieces of jewelry were created by the class of eight participants. The one day jewelry extravaganza is becoming popular and so much fun that folks are repeating the experience by coming back for seconds.

Here are a few samples of pieces created.

This is a before and after shot just to show what happens to the glass. Glass tends to 'ball-up' or pull into itself when heated. In fact, if you heat a square long enough it will turn round. When you realize this, then you can use that as part of your overall design for a piece.

This is another before and after example. This is a special glass called miliefiori which means millions of flowers in French.The color arrangements in miliefiori are made in long fat bars of glass which might be 2 to 3 inches thick and a foot long. The thick bar of glass is heated and pulled and stretched like taffy into a very thin 1/4 inch thick rod, shrinking the design down in the process. You may get twenty small rods from the stretched out bar. The rods are then cut into small sections, and we use these little nips off of the rod in our class to make jewelry.

The image to the left are a collection of random pieces made from a glitzy type of glass called dichroic glass.

The one to the right is made from a mixture of dichroic and regular glass. A piece like this just take a few minutes to make, because I supply many kinds of glass to choose from, and in this case the glass was prefired. All the the student had to do is mount the colored glass on a black background. Of course, the black glass had to be cut by the student to fit the size of colored glass she chose.

The one to the right is made from a mixture of dichroic and regular glass. A piece like this just take a few minutes to make, because I supply many kinds of glass to choose from, and in this case the glass was prefired. All the the student had to do is mount the colored glass on a black background. Of course, the black glass had to be cut by the student to fit the size of colored glass she chose.

At a Have Kiln Will Travel event the emphasis is on fun. We literally play with glass and all the glass options I provide. Some students make so many pieces and so quickly that there are always a few pieces left over that no one recognizes as theirs. We don't allow orphans so someone always steps up to claim the work of art by an unknown artist.

The image to the left is a wine stopper. There are many items made that are not jewelry such as bookmarks, push pins, belt buckles, office spring clips for paper, refrigerator magnets, and money clips. I have not been successful with getting many guys to the events so far. They must hear the work 'jewelry' and get turned off. Too bad. The class is for anyone who likes color and a chance to melt glass into useful personal items or gifts.

Maybe if I brought in a torch to melt glass the guys would sign up. Don't think that will happen though.

Here are a few samples of pieces created.

This is a before and after shot just to show what happens to the glass. Glass tends to 'ball-up' or pull into itself when heated. In fact, if you heat a square long enough it will turn round. When you realize this, then you can use that as part of your overall design for a piece.

This is another before and after example. This is a special glass called miliefiori which means millions of flowers in French.The color arrangements in miliefiori are made in long fat bars of glass which might be 2 to 3 inches thick and a foot long. The thick bar of glass is heated and pulled and stretched like taffy into a very thin 1/4 inch thick rod, shrinking the design down in the process. You may get twenty small rods from the stretched out bar. The rods are then cut into small sections, and we use these little nips off of the rod in our class to make jewelry.

The image to the left are a collection of random pieces made from a glitzy type of glass called dichroic glass.

The one to the right is made from a mixture of dichroic and regular glass. A piece like this just take a few minutes to make, because I supply many kinds of glass to choose from, and in this case the glass was prefired. All the the student had to do is mount the colored glass on a black background. Of course, the black glass had to be cut by the student to fit the size of colored glass she chose.

The one to the right is made from a mixture of dichroic and regular glass. A piece like this just take a few minutes to make, because I supply many kinds of glass to choose from, and in this case the glass was prefired. All the the student had to do is mount the colored glass on a black background. Of course, the black glass had to be cut by the student to fit the size of colored glass she chose.At a Have Kiln Will Travel event the emphasis is on fun. We literally play with glass and all the glass options I provide. Some students make so many pieces and so quickly that there are always a few pieces left over that no one recognizes as theirs. We don't allow orphans so someone always steps up to claim the work of art by an unknown artist.

The image to the left is a wine stopper. There are many items made that are not jewelry such as bookmarks, push pins, belt buckles, office spring clips for paper, refrigerator magnets, and money clips. I have not been successful with getting many guys to the events so far. They must hear the work 'jewelry' and get turned off. Too bad. The class is for anyone who likes color and a chance to melt glass into useful personal items or gifts.

Maybe if I brought in a torch to melt glass the guys would sign up. Don't think that will happen though.

Friday, February 5, 2010

ArtiCulture Jewelry Samples

These are some of the glass art jewelry made during a recent class at ArtiCulture. It is always amazing to see what designs are done in just a few minutes of exploring the potential of glass, mica, frit, stringers, powder and so many other creative elements. I think I still talk too much at the start of the class. I'm trying to distill the Do's and Dont's into a short 15 minute overview then just let the attendees run wild with all the glass potentiality!

See Registration Links to the left and the calendar for future event location and dates.

See Registration Links to the left and the calendar for future event location and dates.

Friday, January 29, 2010

OMG! Glass Fusing Classes Gone Wild!

"Ask and you shall receive." Well I've been asking and now I'm receiving! Over the next few months I'll be at eight locations, and teaching stained glass, Intro to Fused Glass, Designing With Glass, as well as the Glass Jewelry class. I think I'll also be adding an Intro to Enameling class, but I haven't designed the course yet.

All of this and Have Kiln Will Travel events have not even started. I wanted to secure two locations for the HKWT events before I actively begin the process of marketing the concept. Initially I was just going to have HKWT events on the calendar, but I decided to show all classes/events whether they are art center classes where I'm just teaching, or, classes where I am taking kilns to locations to teach, or, HKWT events where I pack up the kilns for a specific fundraising event.

This is a great start. Other opportunities are grants for teaching which I've applied for, and just plain old private lessons.

I'm closing in on my second HKWT hosting site and will post both locations in the near future. I'll then be ready to set sail on this adventure!

All of this and Have Kiln Will Travel events have not even started. I wanted to secure two locations for the HKWT events before I actively begin the process of marketing the concept. Initially I was just going to have HKWT events on the calendar, but I decided to show all classes/events whether they are art center classes where I'm just teaching, or, classes where I am taking kilns to locations to teach, or, HKWT events where I pack up the kilns for a specific fundraising event.

This is a great start. Other opportunities are grants for teaching which I've applied for, and just plain old private lessons.

I'm closing in on my second HKWT hosting site and will post both locations in the near future. I'll then be ready to set sail on this adventure!

Thursday, January 7, 2010

Relationships & Testing

It has been well over four months since I first thought of the Have Kiln Will Travel (HKWT) idea. The first steps were field test just the idea, then develop and test the class material, then obtain the LLC standing and insurance, and I'm sure I'll be refining the processes over time for the next year.

One recent refinement was testing the kilns on 15 amp circuits instead of the 20 amp which I first thought was required for the kilns. I was pleasantly surprised to find that you can run 2 kilns on a 15 amp circuit and have a dozen lights on at the same time. This is significant because 15 amp circuits are common, and 20 amp are less so. This eliminates one of the major stumbling blocks of holding HKWT events.

I've also been working on the other major problem of where to hold the events. I found two local art centers which are willing and I will go into detailed discussions with them next week. These type of relationships are key to making the whole concept work.

One of the last steps will be to form relationships with local nonprofit support groups, fund raising groups, and event planners. It is my hope that these type of organizations will help me get the HKWT story out.

One small victory every day is becoming my motto.

One recent refinement was testing the kilns on 15 amp circuits instead of the 20 amp which I first thought was required for the kilns. I was pleasantly surprised to find that you can run 2 kilns on a 15 amp circuit and have a dozen lights on at the same time. This is significant because 15 amp circuits are common, and 20 amp are less so. This eliminates one of the major stumbling blocks of holding HKWT events.

I've also been working on the other major problem of where to hold the events. I found two local art centers which are willing and I will go into detailed discussions with them next week. These type of relationships are key to making the whole concept work.

One of the last steps will be to form relationships with local nonprofit support groups, fund raising groups, and event planners. It is my hope that these type of organizations will help me get the HKWT story out.

One small victory every day is becoming my motto.

Subscribe to:

Posts (Atom)